| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Vector |

| Model Number : | VEC-VC1-00623MC-M-E /130MB-1R525A23F-CF2 |

| Certification : | CE |

| Price : | To Be Discussed |

| Payment Terms : | L/C, T/T, Western Union |

| Supply Ability : | 500-1000 kits /Month |

| Delivery Time : | 5-8 work days |

220V 1.5kw Pulse/Analog AC Servo Driver System For Sewing Machine

Pulse/Analog AC Servo Driver System

AC Power 1.5KW

Three Phase 220V

Modbus / CanOpen / EtherCAT

Location / Speed / Torque Control Mode

2500 pulse incremental + Hall encoder;

Products Features

| Product Name | Pulse/Analog AC Servo Driver System |

| Brand | Vector |

| Model No. | VEC-VC1-00623MC-M-E /130MB-1R525A23F-CF2 |

| Power4 | 1.5KW |

| Voltage | 220V |

| Phase | Three Phase |

| Rated Current | 6A |

| Communication Protocols | Modbus/CANopen/EtherCAT |

| Encoder | 2500 pulse incremental + Hall encoder; |

| Voltage | Control Mode | Single-phase / three-phase full-controlled rectification SVPWM modulation |

| Encoder | Encoder Feedback | 2500 pulse incremental + Hall encoder; 2500 pulse incremental; 17bit Tamagawa absolute encoder; 23bit Tamagawa absolute encoder; 24bit Nikon absolute encoder; |

| Pulse Command Input | Pulse Type | Differential input,Open collector |

| Frequency Range | Differential input:0-500kHz,pulse width greater than 1us Open collector: 0-300kHz,pulse width greater than 2.5us | |

| Pulse Mode | pulse + direction; AB pluses; CW+CCW; | |

| Analog Input | Voltage Range | -10V to 10V |

| Input Impedance | 10kΩ | |

| Maximum Frequency | 1.5kHz | |

| DI/DO Interface Type | NPN/PNP | |

| Communication | Modbus/CANopen/EtherCAT | |

| Location Mode | Command Input Method | Pulse Command Internal Planning Position Plan by target position, speed, acceleration and deceleration time Trapezoidal speed curve Cubic speed curve Absolute / relative command mode |

| Instruction Smoothing Mode | Low Pass Filtering / Median Filtering | |

| Electronic Gear Ratio | N/M;(M=1~2147483647,N=1~2147483647) | |

| Torque Limit | Internal Torque Limit / Analog Torque Limit | |

| Feedforward Compensation | Speed Feedforward / Torque Feedforward | |

| Torque Compensation | Fixed Torque Compensation / Analog Torque Compensation / Automatic Torque Compensation; | |

| Speed Contol Mode | Command Input Type | Pulse Frequency / Analog / Internal Planning Speed |

| Speed Control Range | 1~max speed | |

| Bandwidth | 1kHz | |

| Torque Limit | Internal Torque Limit / Analog Torque Limit | |

| Instruction Smoothing Mode | Low Pass Filtering / Median Filtering | |

| Feedforward Compensation | Torque feedforward | |

| Torque Compensation | Fixed Torque Compensation / Analog Torque Compensation / Automatic Torque Compensation; | |

| Torque Control Mode | Command Input Type | Internal Torque Reference / Analog Control Torque |

| Torque Compensation | Fixed Torque Compensation / Analog Torque Compensation / Automatic Torque Compensation; | |

| Speed Limit | Internal Speed Limit / Analog Speed Limit | |

Servo Drive model slecting:

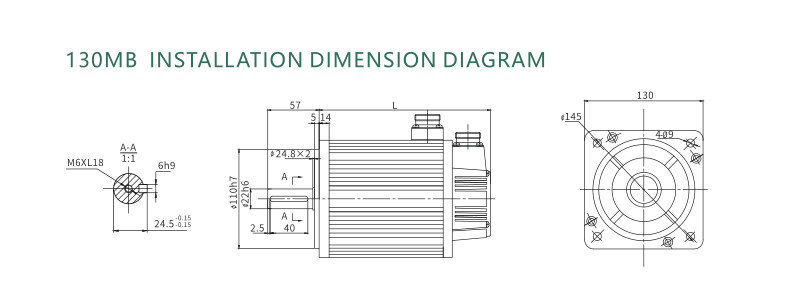

Servo motor model slecting:

Installation Precautions

● Install the driver on a dry and sturdy platform. Maintain good ventilation and

heat dissipation during installation and maintain good grounding.

● Please install in the specified direction to avoid malfunction.

● When installing, please ensure that the servo driver is kept at a specified

distance from the inner surface of the cabinet and other machines, otherwise it may cause fire or malfunction.

| Installation Environment Requirements | Atmospheric Pressure | 86~106kPa |

| Mbient Humidity | 0~55℃ | |

| Ambient Temperature | 0~90%RH | |

| IP Rating | IP20 | |

| Vibration | 0~4.9m/s^2 |

Operating precautions:

● in the test operation, in order to prevent accidents, please test the servo motor with no load

(not connected to the driver shaft), otherwise it may cause injury.

● when starting to operate on the supporting machine, set the user parameters that match the machine

in advance. If you start operation without parameter setting, it may cause mechanical loss or malfunction.

● to avoid accidents, install a limit switch or a stopper at the end of the movable part of the machine,

otherwise it will cause mechanical damage or injury.

● do not make extreme changes to the parameter settings, as this may result in

unstable operation, mechanical damage or injury.

●when the power is turned on or the power supply is cut off, the heat sink of the servo driver, external

braking resistor, motor, etc. may be in a high temperature state. Do not touch it, otherwise it may cause burns.

● when using a servo motor on the vertical axis, set a safety device to prevent the work piece from falling

under alarm, over travel, etc. In addition, please perform the servo lock stop setting when an over travel occurs,

otherwise the work piece may fall in the over travel condition.

● do not enter the operating range of the machine during operation, otherwise it will cause injury.

● do not touch the servo motor or the movable part of the machine during

operation, otherwise it will cause injury.

● please set up the safety system to ensure safety even in the event of a signal

line breakage. For example, when the positive over travel switch (P-OT) and negative over travel switch

(N-OT) signals are disconnected at the factory setting, they operate safely.

● be sure to set the servo OFF state when turning off the power.

● do not turn the power on/off frequently. After the actual operation starts, the power ON/OFF interval

should be more than 1 hour, otherwise the components inside the servo unit will be prematurely aged.

●when an alarm occurs, reset the alarm after the cause is removed and ensure

safety, and restart the operation, otherwise it may cause injury.

● do not use the brake of the brake motor for normal braking, otherwise it may

cause a malfunction.

Maintenance and inspection Precautions

● do not change the wiring while the power is on, otherwise it may cause electric shock or injury.

● please perform wiring or inspection by professional technicians, otherwise it

may cause electric shock or product failure.

● please check the power after the power is off for at least 5 minutes. Even if the power is turned off,

high voltage may remain inside the servo drive. Therefore, do not touch the power terminal within 5

minutes after the power is turned off, otherwise it may cause electric shock.

●when replacing the servo drive, please back up the servo driver user parameters to be replaced

before the replacement, and transfer the backup to the new servo drive, and then restart the operation,

otherwise the machine may be damaged.

Packing and Shipping

| Packing details of Servo Drive | |||||

| Products | E1(3-6A) | E2(7-12A) | E3(16-27A) | C015(32-38A) | C022(45-60A) |

| Ctn. Size | 280*208*78 | 280*208*112 | 375*290*155 | 440*296*288 | 510*305*325 |

| Packing details of Motion Controller | |||||

| Products | VA Motion | VA Expansion | VE Motion | VE Expansion(32) | VE Expansion(76) |

| Ctn. Size | 176*165*78 | 127*75*70 | 144*128*69 | 176*164*78 | 316*164*78 |

Delivery Time

| Quantity | 1-5 kits | 50-100 kits | 200-500 kits |

| Delivery time | Within 3 days | 5-10 days | 15-25 days |

1. For small order we always can delivery out within 1 week.

2. Our products can be shippied via Air, Land or Sea.

Accessories

| Accessory name | Image | ||

| Satandard Spare Parts | Power terminal |  | Adapt to E1,E2 structure drive |

| Cn3 encoder plug | Encoder plug on the driver side | ||

| Cn4 control terminal plug | Input/output signal terminals,user wiring | ||

| Encoder connection line | The standard cable length is 3, 5, 8, 10, 13, 15 meters, according

to customer needs Provide independent connector | ||

| Power line | The standard cable length is 3, 5, 8, 10, 13, 15 meters, according

to customer needs Provide independent connector | ||

| Drive monitoring line | Connect and adjust the software for remote monitoring and firmware update | ||

| Purchasing Spare Parts | USB to RS232 Adapter cable | If necessary, self purchase | |

| Ethernet communication line | If necessary, self purchase |

CE Certificates

1. CE (EU Safety Standard);

2. IEC/EN61800-5-1:2007 (Safety requirements for electrical,

thermal and energy in Section 5-1 of the

variable speed electric driver system), corresponding to the national standard GB12668.501-2013;

3, IEC / EN61800-3: 2004 + A1 (speed control electric driver system part 3 electromagnetic compatibility

standards and its specific test methods), corresponding to the national standard GB12668.3-2012.

Our Team

|